Rethinking the way we use resources and make products

Through the eighteenth and nineteenth centuries, the industrial revolution fundamentally transformed our ability to manufacture products. Supported by scientific discoveries that simplified the extraction of raw materials and by the abundance of readily available labour, the transformation in manufacturing processes made it possible to produce goods on a mass scale for the first time in human history.

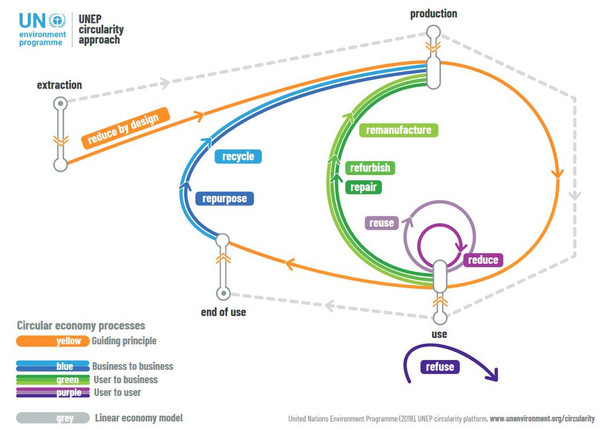

Ever since, constant innovations in the manufacturing and design of goods gave us access to products made in different parts of the world, at an affordable price. But the real cost of a product – social, political, environmental - is not reflected on its price tag. This model of the economy, which consists of taking resources, using them to make a product, which is then being consumed and discarded – also known as the linear model – is no longer viable. It is highly wasteful, polluting, and unsustainable in the long run.

The circular economy (CE), on the other hand, whose underlying principles include designing out waste and pollution, extending the lifespan of products and materials through re-purposing and reuse, and regenerating natural systems, has a potential to transform unsustainable production and consumption patterns. Globally, many countries and businesses have initiated circular economy strategies that aim to transform production chains and consumption habits. As those strategies differ widely among different stakeholders, so do the concepts and terms used to describe their underlying mechanisms: circular economy, bioeconomy, green economy, and others.

While the concept of the circular economy used here remains quite broad and leaves room for flexible interpretation, its core principles include: 1) designing out waste and pollution by creating and optimizing products for a cycle of disassembly and use, and in that way saving labour and energy that would be lost during waste disposal and recycling, and 2) making the most out of both consumable and durable components of a product, by returning the former into the biosphere through processes like composting and anaerobic digestion (e.g. food, cotton, or wood) and repairing, re-purposing, or upgrading the latter (e.g. electronics) towards a different use.

It is important to note that the circular economy is not a guarantee for sustainability. For the circular economy to be sustainable, it needs to be based on renewable sources (thus avoiding fossil-based and other non-renewable materials with large environmental footprint) and the use of bio-based products should not have a negative impact on ecosystems, the climate, food systems, and so on.

Circularity and the forest sector

The principles of the circular economy are well aligned with common practices in the forest sector and in the manufacturing of forest-based products. The lynchpin of circularity, which is minimizing waste and maximising efficiency reflects the goals of sustainable forest management.

Many tenets of the circular economy are already applied in the forest sector. Wood products used for construction purposes contribute to a lower carbon footprint of buildings. Wood, cellulose and its derivates (such as lignin) are a viable substitute for non-renewable materials. Also, reuse and repurposing materials through lumber salvage and paper recycling are common practices in the sector.

As such, forests and forest-based products can play a key role in the circular economy by providing a renewable source of raw materials. A more coordinated approach aiming to tap into the full potential of the forest sector can turn this sector into one of the key pillars of the circular economy.

Circular economy and wood-based value chains

The construction sector is characterized by one of the highest carbon footprints: an estimated 39 percent of all global carbon emissions stem from the building and construction sector.

With the rise of engineered wood products, wood has increasingly been used in the construction of residential and office buildings. The integration of circularity principles into this sector can further contribute to a transition towards a sustainable, low carbon economy, reducing carbon emissions and waste on a mass scale.

One construction technique appears to be very interesting from the circular economy perspective. The “off-site construction" is the planning, design, fabrication and assembly of building elements at a location other than their final installed location to support the rapid and efficient construction of a permanent structure. This technique is characterized by an integrated planning and supply chain optimization strategy and minimum waste.

Another sector - the textile fibres industry, could increase its circularity through a stronger link with forests and the use of wood-based products. Over the years, the sector has received growing public attention due to a “fast fashion” production model that is based on extensive extraction of raw materials (synthetic fibres made from non-renewable petroleum dominate the market), pollution and waste.

The environmental costs of fast fashion, once accounted for greenhouse gas emissions, excessive use of water and toxic chemicals, far exceed its retail price. Sourcing alternative materials with a lower carbon and water footprint, such as modern man-made cellulosic fibres, and improving clothing collection and recycling infrastructures are important for moving towards a circular economy.

Discover our work on the circular economy

Country needs and future opportunities

For more information on this work, please contact Ms Alicja Kacprzak, Forestry Officer at the UNECE/FAO Forestry and Timber Section.